Best Products and Solutions for Concrete Floor Polishing

DECO CRETE’s concrete polishing transforms floors into glossy, durable, and easy-to-clean surfaces. These solutions enhance aesthetics, boost slip and dust resistance, reduce maintenance costs, and increase property value. Environmentally friendly, they help create safe, professional spaces with long-lasting performance.

What is Concrete Polishing?

Concrete polishing is the process of treating the surface of a concrete floor. Using DECO CRETE’s solutions and products, concrete floors become glossy, durable, sturdy, easy to clean, and long-lasting.

DECO CRETE’s concrete polishing solutions aim to improve the aesthetics and durability of the floor. When the floor is treated with DECO CRETE solutions, its surface becomes glossy and resistant to wear over time. Additionally, DECO CRETE’s polishing solutions enhance the floor’s durability, slip resistance, and dust resistance, making cleaning and maintenance much easier.

Using DECO CRETE’s concrete polishing solutions also brings many other benefits, such as enhancing the aesthetic appeal of a space, reducing maintenance and repair costs, increasing property value, and creating a safe and professional work environment. These solutions are also environmentally friendly, helping to minimize waste and conserve resources.

Why Choose DECO CRETE’s Products and Solutions for Polished Concrete Floors?

Deco Crete is a leading brand specializing in concrete polishing chemicals in Vietnam and Europe. We are currently partners with many top contractors and factory owners in Vietnam, providing solutions for polished concrete flooring in large-scale projects and industrial facilities.

Deco Crete’s products offer optimal solutions for customers, fully meeting the needs of concrete hardening, protection, repair, and polishing.

Additionally, DECO CRETE has a team of professional technicians ready to support customers and closely monitor the construction process.

DECO CRETE’s Concrete Polishing Solutions

At DECO CRETE, we have conducted extensive research and testing on various products and solutions for concrete floor protection to identify the best and most cost-effective concrete polishing solution in terms of quality and efficiency.

Some of DECO CRETE’s Solutions:

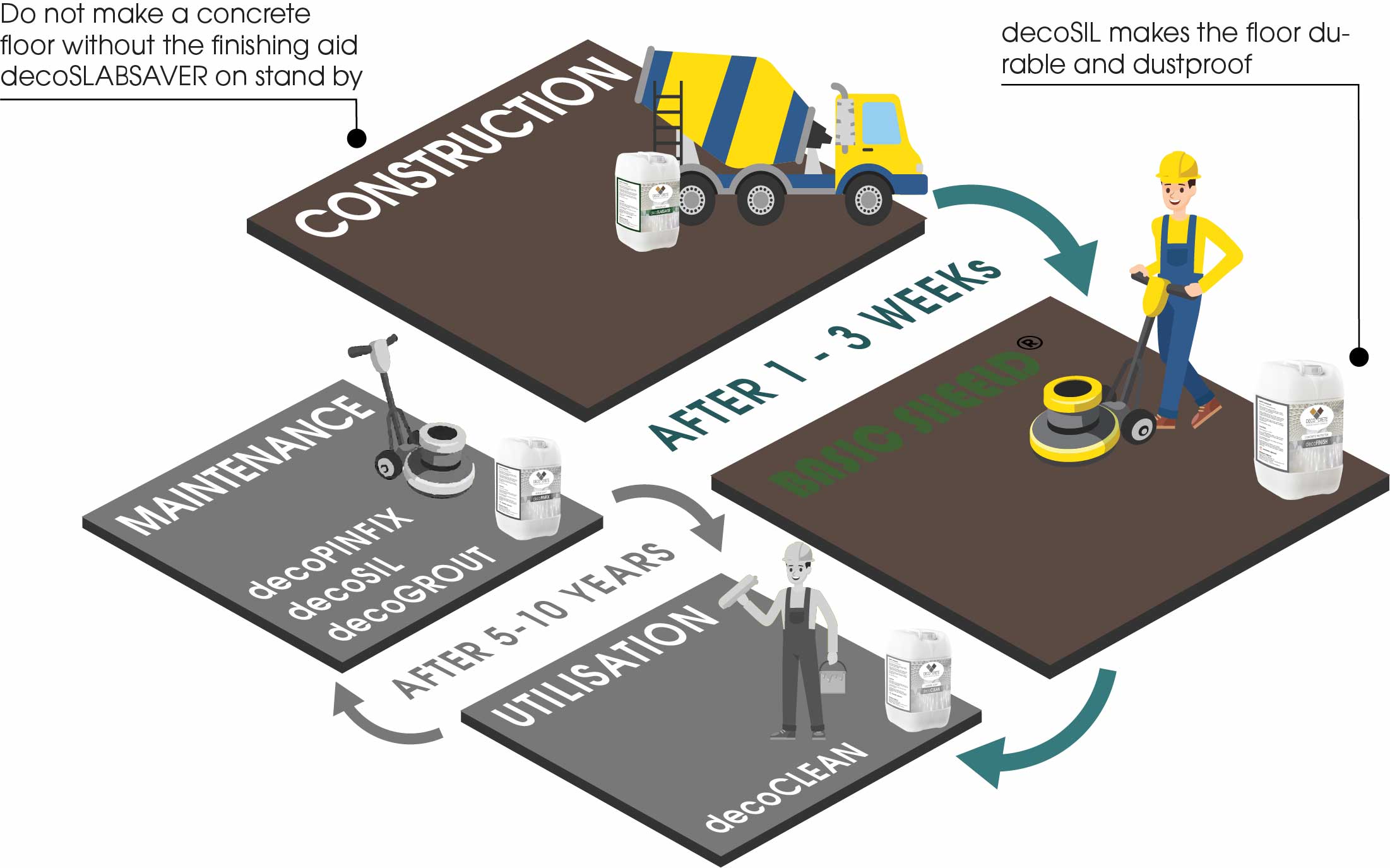

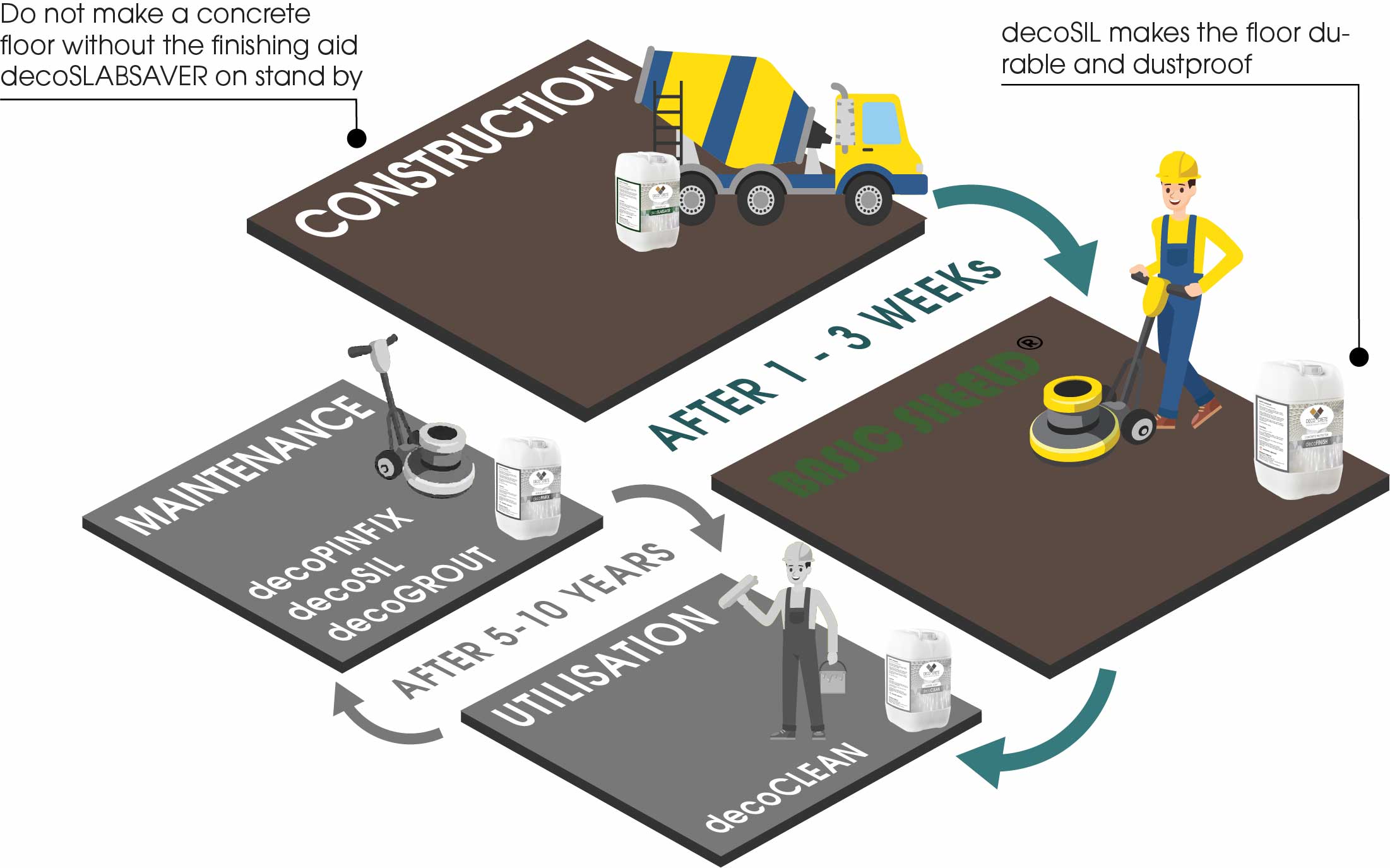

BASIC SHEELD

BASIC SHEELD is a basic treatment of a concrete floor using the liquid hardener decoSIL. The best floor preparation is a polishing step with resin 200, followed by the decoSIL application and consequently a polishing step with resin 400.

- Product used: decoSIL

- Features: durable, dust-free

COLOR SHEELD

Giving a permanent color to an existing concrete floor is possible with the penetrating, water-based dye decoCOLOR. After applying decoCOLOR, the surface has to be densified and sealed with decoSIL and decoFINISH.

- Product used: decoPREP, decoCOLOR, decoSIL, decoFINISH

- Features: durable, dust-free, stain and tire mark resistant, easy to clean, choice of many colors

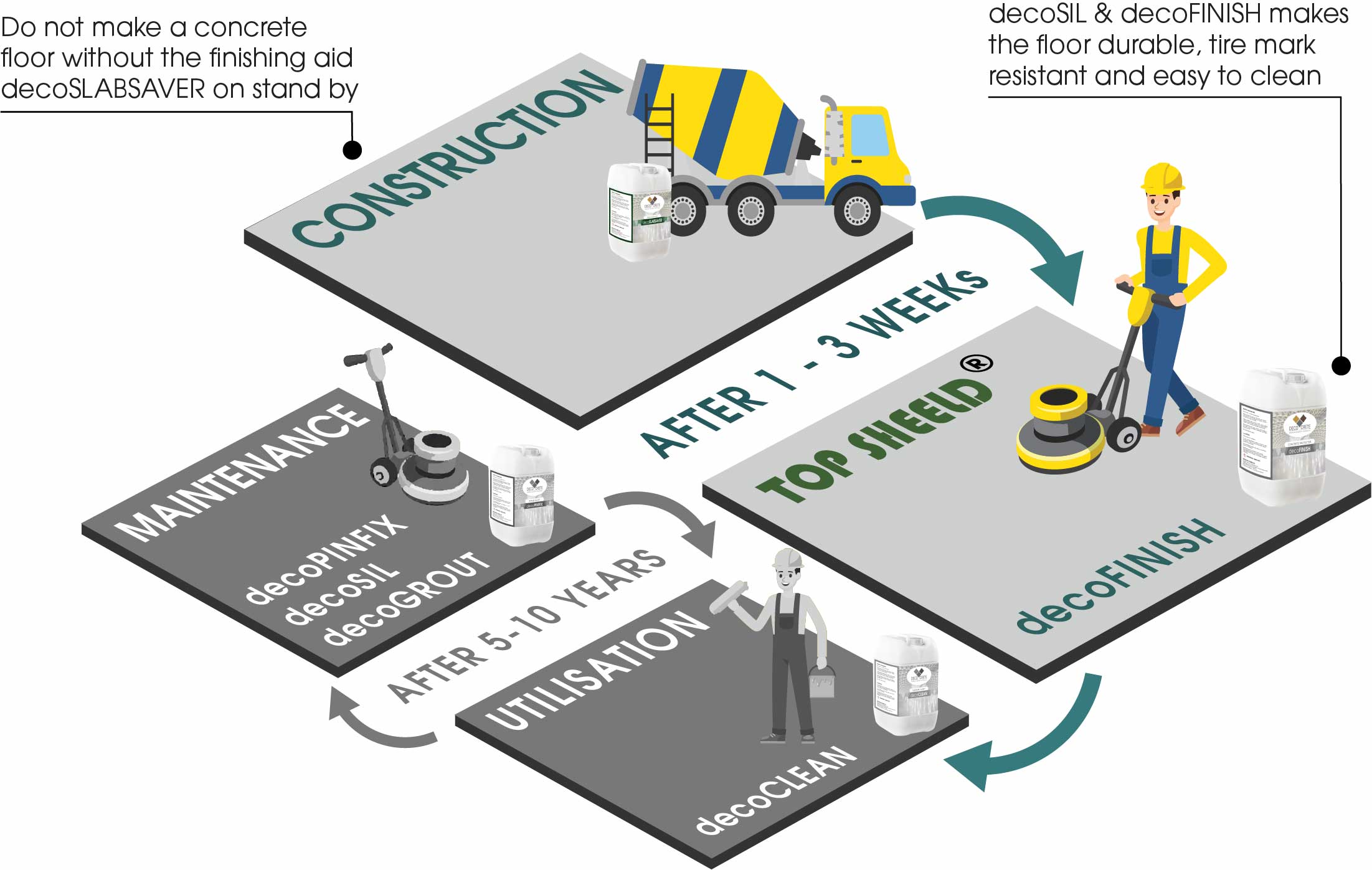

TOP SHEELD

TOP SHEELD is a 4 steps polish (grits 100/200/400/800) suitable for existing concrete floors, which are flat and do not have many low spots. The products decoSIL and decoFINISH make a floor treated with a Deco Crete’s TOP SHEELD hard, abrasion resistant, easy to clean and tire mark resistant.

- Product used: decoSIL, decoFINISH

- Features: durable, dust-free, stain and tire mark resistant, easy to clean

AGGREGATE SHEELD

This is a polishing treatment with large aggregate exposure which includes 1 or 2 grinding steps followed by a step with decoQUICKCUT to remove scratches. Only 2 more polishing steps are needed as well as the application of decoPINFIX and decoFINISH.

- Product used: decoQUICKCUT, decoSIL (optional), decoPINFIX (optional), decoFINISH

- Features: durable, dust-free, stain and tire mark resistant, easy to clean, large aggregate exposure

COMBO SHEELD

COMBO SHEELD is a state of the art treatment for new concrete floors. It is a dual treatment consisting of an application of decoSLABSAVER on fresh concrete during the construction phase, followed 1 week later by the application of decoFINISH.

- Product used: decoSLABSAVER, decoFINISH

- Features: durable, dust-free, stain and tire mark resistant, easy to clean, short in construction time

RETRO SHEELD

This is a floor renovation treatment with large aggregate exposure which includes 1 or 2 grinding steps followed by a step with decoQUICKCUT to remove scratches. Only 2 more polishing steps are needed as well as the application of decoPINFIX and decoFINISH.

- Product used: decoQUICKCUT, decoSIL, decoPINFIX, decoGROUT, decoFIX, decoFINISH

- Features: durable, dust-free, stain and tire mark resistant, easy to clean, large aggregate exposure

Advantages of Polished Concrete Floors

Enhanced Aesthetics:

The concrete floor polishing process creates a glossy surface, significantly enhancing the aesthetic appeal of the floor

Increased Hardness and Durability:

The polishing process uses chemical products to increase the hardness and durability of the concrete floor. This helps minimize the impact of external factors such as rain, sunlight, wind, abrasion, and scratches.

Reduced Maintenance Costs:

Polished concrete floors require less time and money for maintenance and repair. This helps save costs for maintaining your concrete floor over the long term.

Environmental Protection:

The concrete floor polishing process does not use harmful chemicals and produces no waste. Therefore, it is a safe and environmentally friendly option for renovating and decorating your concrete floors.

Some Basic Steps for Using DECO CRETE’s Concrete Polishing Solutions

Step 1: Use a grinding machine to inspect and repair all defects on the concrete floor surface. It’s recommended to use a concrete floor grinding machine combined with grinding discs to treat the surface. Handheld grinding machines can be used for corners and areas near walls.

Step 2: Clean the surface thoroughly with water and dye the concrete floor if requested by the client.

Step 3: Apply a hardening chemical to the concrete surface and wait for 15–30 minutes (depending on weather conditions) to allow the hardening chemical to penetrate the concrete.

Step 4: After applying the hardener, use a gloss-enhancing chemical on the concrete surface. Based on the client’s requirements and desired level of gloss, the construction team can select suitable products.

Step 5: Wait 30–60 minutes after applying the gloss-enhancing chemical (depending on weather conditions) and begin polishing the concrete floor using a heatpad. Depending on the area and location, appropriate polishing methods should be used to ensure the floor meets client expectations.

Step 6: Prepare an acceptance record and hand over the project.

Precautions Before and During Concrete Floor Polishing:

- The polishing process should be carried out by experienced professionals with adequate equipment to ensure the best results.

- Choose appropriate products and concrete polishing solutions and master the necessary polishing techniques—these are fundamental conditions before starting construction.

- Keep the floor clean: Cleaning the floor thoroughly before and after construction each day helps maintain the floor, saves time and costs, prevents long-term stains, and facilitates easier and faster polishing.

- Use specialized chemicals: Depending on the project’s requirements, select suitable chemicals for cleaning, hardening, and polishing concrete floors. Products like decoQUICKCUT can be used for both polishing and hardening concrete surfaces, saving costs and construction time.

- Avoid colored cleaning chemicals: Before polishing, concrete is highly absorbent and prone to discoloration due to colored chemicals, which can affect its aesthetics. Avoid using such products to expedite the process.

Summary

To achieve a shiny, durable, and aesthetically pleasing concrete floor, DECO CRETE’s products and solutions will exceed your expectations. Concrete floors will become:

- Glossy

- Sturdy

- Dust-resistant

- Abrasion-resistant

- Easy to clean

- Maintenance-friendly

- Construction and maintenance costs will be optimized.

If you are searching for the optimal concrete polishing solution, feel free to contact us for consultation and answers to your questions.

Note: The concrete floor Polishing process is complex and should be carried out by experienced professionals.

Name: DECO CRETE

Adress: 1484 Nguyen Duy Trinh street,Long Truong ward, Thu Đuc city, HCM city

Phone: 02836366302

Website: https://decocrete.eu/best-products-solutions-polishing-concrete/

Email: [email protected]

Tags: Polishing, Polishedconcrete, industrialflooring, concretesealing, liquidhardener, concretefloors, concrete Polishing, Polished concrete solutions